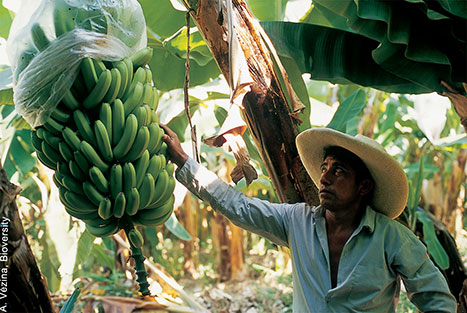

Organic banana production in Peru

Almost all of Peru’s exported bananas are organic, accounting for around 3% of global organic banana production.

In 2014 production occupied around 5 500 ha, close to 4% of the total banana producing area. This was concentrated in the northern regions of Piura, Tumbes and Lambayeque, and produced mostly by smallholders with farms of less than 3 hectares. Since the country started the conversion from conventional to organic in the late 1990s, more than 80% has become concentrated in the Chira Valley in Piura1.

- In Peru between 2010 and 2015, organic banana production increased by 94%2.

- 5% of bananas produced in Peru are exported by close to 7 000 small farmers.

- Between 2014 and 2015 exports increased by 19%, reaching US$143 million and close to 190 000 tonnes3.

- Bananas from Peru are exported to 15 countries. The most important destination is the United States, followed by the Netherlands, Germany, Belgium, South Korea, Finland and Japan4.

Factors influencing the development of organic banana production in Peru:

- Low levels of rainfall in growing areas significantly reducing investment in drainage.

- Low incidence of Black Sigatoka.

- Favourable tropical humid climate and weather conditions.

- Organization of small farmers, who have grouped together creating associations, allowing them to be more competitive in international markets, to have improved bargaining power and better prices.

- A beneficial tariff agreement between the EU and Latin America, in plce since 2012, has encouraged overall banana exports from Peru, thereby also increasing organic production.

Example of Solidaridad5

Solidaridad is an international non-profit organization with more than 45 years of experience working for the sustainability of commodity supply chains. In Peru, Solidaridad works with the organic banana production chain through its fruit program, involving main stakeholders in more efficient, resilient and responsible agricultural production. The organization has been one of the key promoters of the Peruvian banana commercial chain, helping the first banana producers to become certified, organized and empowered. The following organic production process has been demonstrated on farms in Peru associated with Solidaridad:

The process step by step

1. Field selection

a. Fields should be located near a route of access and water source.

b. A topographic plan is developed, in order to properly locate the irrigation and drainage infrastructure.

c. Before soil preparation, analysis and excavation of pits should be made to study soil profiles.

2. Preparing the ground

a. If there is compaction, a tractor-towed deep plow with up to 40 cm chisels should be used. A subsoiler can be used in extreme cases of compaction.

b. Chisel plows facilitate vertical penetration of roots, increasing drought resistance, breaking the hard layers of soil and facilitating the exchange of gases in the soil.

3. Digging

a. The soil should be moistened and then a pit 0.40 m × 0.40 m × 0.40 m should be dug. The size of the seed should be considered. Superficial sowing affects the production of the plant, as a result of the effect of short or prolonged periods of drought. It is important to note that the soil of the surface layer or topsoil (30 cm) has higher content of organic matter and nutrients than the lower layers.

b. It is important to dig several days before planting to encourage aeration and to add a layer of compost. 1 kg of compost can be used, as well as 300 g of guano and 100 g of Sul-Po-Mag. The mixture is placed at the bottom of the pit, so that later it nurtures the roots. Phosphate rock can be added, if there is a phosphorus deficiency.

4. Selection of the seed

a. The seed must come from organically certified production centers. The plants must be free of pathogens, vigorous, and with sustained production, producing between 12 and 13 commercial hands, with suckers that measure 1.5 m.

5. Extraction and selection of suckers

a. Extraction is performed when the ground is wet. The aim is to extract suckers that have three or more functional sword-shaped leaves, with a minimum height of one metre.

b. To be planted as corms, very large suckers or those transported over large distances are cut between 5 and 10 cm above the neck and at an angle, so that liquid substances can drain, preventing rot. The suckers are classified by size, and at the time of planting are planted in order of size and thickness. Larger seeds have a shorter harvest period.

6. Cleaning and washing of suckers

a. From the sucker, remove the remaining earth with water, as well as the roots and parts of the corm damaged by pests or micro-organisms. The aerial portion should also be removed.

b. It is preferable to dispose of severely damaged corms. When cleaning the corm, the "crown buds" located around the seed should not be damaged.

7. Disinfection of the seed

a. The corms should be immersed in a solution of 5 ml of chlorine per litre of water for three minutes. Alternatively, the corm can be soaked in water heated to a temperature of between 50 °C and 55 °C for 20 minutes.

8. Seeding

a. The seed should be placed in the pit upright, moving what was attached to the plant stem to one side to ensure that clusters appear orderly.

b. Compacting the soil prevents seed rot by removing free spaces where water can pool. The work carried out after planting includes:

Activity | Weeks after sowing |

Desuckering | 10 weeks (2.5 months) |

Elimination of relapses | 12 weeks (3 months) |

Sucker preselection | 14 weeks (3.5 months) |

Sucker selection | 20 weeks (5 months) |

9. Associated crops

a. In new plantations, plant crops with a short vegetative period, preferably legumes, so that they inhibit the development of weeds and limit evaporation caused by the sun.

10. Irrigation

a. Conducted every 15 days in summer and every 20 days in winter.

11. Weed control

a. Manually, without product applications.

12. Fertilization

a. An analysis of soil fertility should be performed before sowing, and after sowing perform one every two years.

A foliar analysis should be conducted to know if the plant is properly assimilating nutrients applied to the soil in the form of fertilizers. Currently three applications (every four months) are made. Fertilizers usually used include:

Fertilizer

| Ha/year

| N Kg/ | P Kg/ | K Kg/ | Ca Kg/ | Mg Kg/ | S Kg/ | |

Sacs | Kg | |||||||

Compost | 180 | 6300 | 75 | 24

| 15 | 0 | 0 | 0 |

Potassium | 15 | 750 | 0 | 0 | 375 | 0 | 0 | 135 |

Guano | 58 | 2900 | 348 | 203 | 58 | 232 | 14 | 43 |

Kimelgran | 4 | 1 | 0 | 1 | 2 | |||

Sul-Po-Mag | 9 | 450 | 0 | 0 | 99 | 0 | 81 | 99 |

Total | 266 | 1500 | 424 | 227 | 551 | 233 | 97 | 277 |

13. Pest control:

a. Implement integrated pest management. Application of organic repellent such as capsaicin-based compounds.

b. Apply calcium polysulfide (caldo Sulfocalcico) to the plantation and soil.

c. Implement of biological controllers like Orius insidiosus, which attacks thrips.

d. Implementation of entomopathogenic fungi: Beauveria bassiana and Lecanicillium applied in the afternoon, and after pods are stripped from their pseudostems.

14. Control of Banana streak virus (BSV):

a. Identify and eliminate plants affected by the disease.

b. Replace infected plants with healthy suckers.

c. Put lime in the area from which infected plants were removed.

d. Provide adequate irrigation to reduce water stress.

e. Reduce damage by other pests and diseases.

f. Reduce competition from weeds.

g. Improve plant nutrition, to generate greater physiological resistance to plant diseases.

h. Remove dry pods to reduce the areas of refuge of cochinilla.

15. Watery rot control:

a. Use healthy seeds.

b. Keep the soil well-drained.

c. Disinfect tools.

d. Space plants widely enough to allow ventilation for rapid drying of foliage.

e. Remove pods from the pseudostem at the appropriate times.

f. Have a suitable fertiliser plan based on soil analysis and the requirements of the crop, with attention paid to the amounts of potassium and boron.

g. Check the presence of weevils, particularly scratch weevils.

h. Cut the pseudostems during the harvest’s wet season to prevent rainwater from accumulating and spreading bacteria.

i. Prevent injuries that allow the entry of the pathogen. Remove all affected plants from the plantation, and sprinkle the hole with 2 kg or 3 kg of lime. Replant in three months, using healthy seeds and applying compost to the bottom of the hole.

16. Control of crown rot:

a. Cover cleaning tanks after filling them with water to avoid spores carried by the wind entering the tanks.

Extract of grapefruit (two to three ml/litre of water), or alum (potassium aluminium sulphate, 400 g/20 litres of water), can be applied via immersion.

Challenges

Organic banana producers in Peru face several challenges:

- Providing an appropriate level of nutrients, in particular enough nitrogen to banana plants. It’s difficult to obtain an organic fertilizer with high enough levels of nitrogen.

- Securing an adequate supply of quality planting material. Many producers secure planting material from their surroundings without checking the quality of the stems.

- Securing sufficient water supplies for irrigation, as supply is limited in areas where bananas are produced in Peru.

- Access to improved production technology to increase yields.

References

References

1 FIBL. Organic World statistics

2 Ministerio de Agricultura y Riego. 2015. Minagri: Exportación de Banano Orgánico Peruano Creció 94% en últimos 5 años

3 FreshPlaza. 2016. Peru: Organic Banana Exports Grow by 19%

4 FreshPlaza. 2016. Peru boosting organic banana production in Piura

5 Data from Solidaridad Peru